The construction industry is responsible for creating the buildings and infrastructure we use daily. But with this progress comes a serious issue: a large amount of waste is produced on job sites.

Much of it ends up in landfills, hurting both the environment and project budgets.

Reducing construction waste is more than just following rules. It leads to smarter building, better business practices, and a more sustainable future.

Whether you’re starting a major new build or working with an experienced building restoration company, making efforts to lower waste and boost efficiency benefits your projects and helps protect nature.

Table of Contents

ToggleWhy Reducing Construction Waste and Improving Efficiency Matter

Why bother thinking about what gets thrown out during construction? The reasons are clear and affect both money and the environment.

Economic and Environmental Effects of Construction Waste

Construction creates a lot of waste — nearly a third of everything thrown into landfills globally comes from these sites. That means wasted resources, energy, and cash.

Materials like concrete, wood, metal, and plastic that could be reused often get dumped instead. This adds to pollution, uses up landfill space, and generates greenhouse gases.

Handling construction waste properly helps the environment, meets government rules, and makes projects run better overall.

How Better Resource Management Saves Money and the Environment

Managing resources well at the job site cuts costs. Less waste means fewer materials to buy, lower disposal fees, and smaller transportation costs to move debris.

Clean, organized sites are safer and more productive. Companies that use better waste practices stand out to clients and stay competitive. This approach is good for business, workers, and nature.

Main Reasons Construction Waste Happens

To cut down on waste, it helps to know where it comes from. Most of the time, it’s not due to bad intentions.

Common waste at job sites includes concrete, metals, plastics, and more. Causes include ordering too much material, damage during delivery or storage, mistakes in cutting, or design changes in the middle of the job.

For example, offcuts and broken materials pile up when there’s no clear process for recycling or reuse.

Problems With Planning and Design

Waste often starts with poor planning. Ordering the wrong amounts, using designs that don’t match normal material sizes, or not thinking about how materials are used or taken apart later all lead to more waste.

Companies that don’t set up clear waste reduction steps from the start often miss ways to save and recycle.

Job Site Mistakes and Weak Processes

Even when planning is good, problems can happen on-site. Errors in cutting, rough handling, weak storage, and poor sorting of waste all add up. If the crew doesn’t know how or why to separate materials, recyclables will often be thrown in with regular trash.

Challenges in Cutting Down Construction Waste

Making waste reduction work isn’t always easy. Construction sites face real problems that need careful solutions.

Huge Amounts and Types of Waste

A lot of different materials are involved, from large pieces of concrete and metal to wood, insulation, and sometimes dangerous materials like asbestos or lead. Sorting and handling all these adds time and money.

No Standard Waste Handling Process

Every site is different. Many companies have no set way to handle waste, so each project may handle materials differently. This inconsistency can lead to missed chances for recycling and poor tracking.

Limited Space and Tough Logistics

Sites often don’t have enough space for sorting or storing waste. Tight schedules make it hard to set up good systems. Moving waste off-site increases costs and complicates the job.

Team Habits and Resistance to New Approaches

Sometimes, changing established routines is the hardest challenge. New sorting steps or careful handling might be seen as slowing down the work. If workers or managers think waste management costs too much or delays projects, they may ignore it. Good results require training, communication, and support from managers.

How to Reduce Construction Waste Before Building Starts

The best way to handle waste is to avoid making it. This begins with early planning.

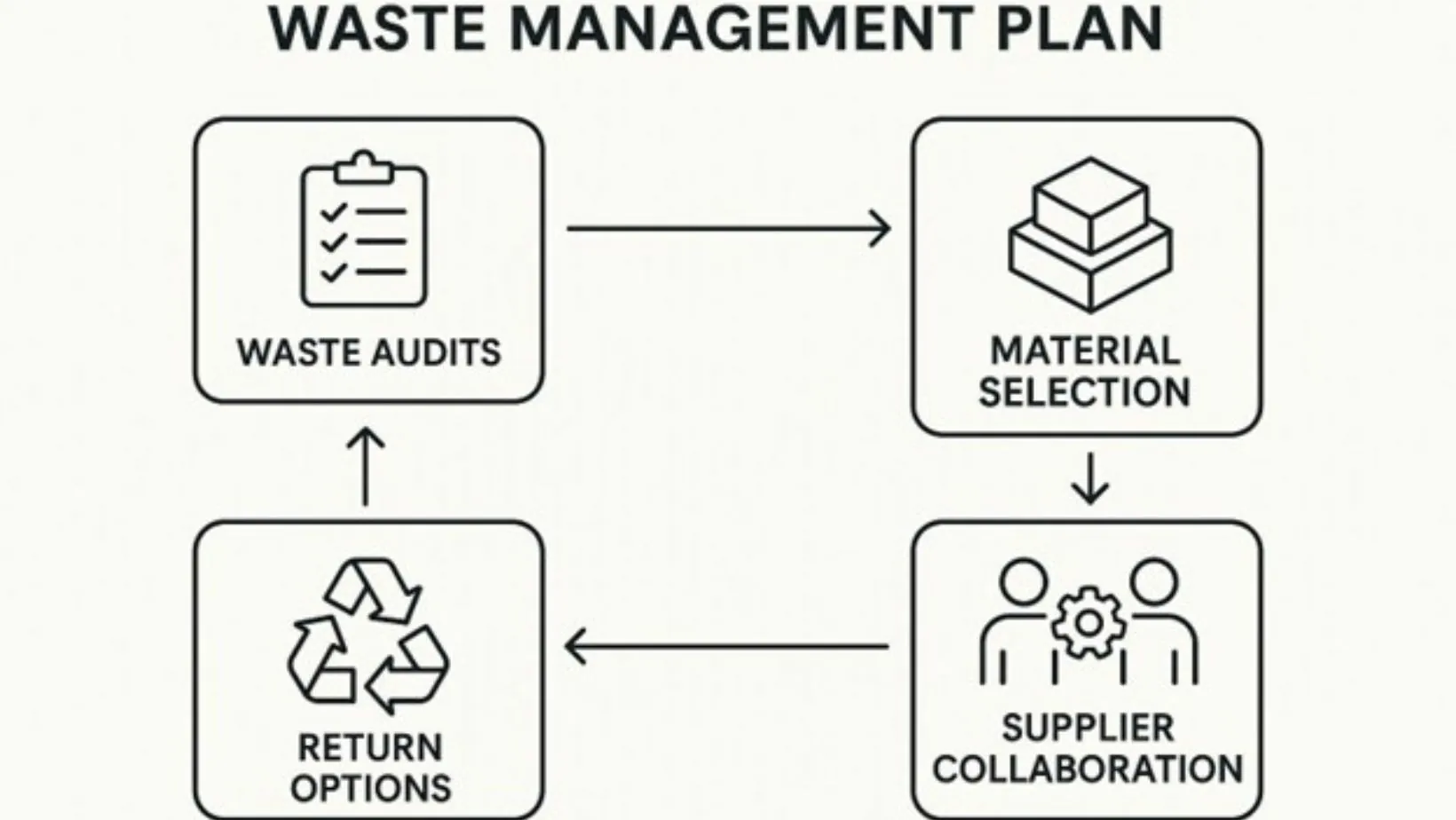

1. Waste Audits and Early Assessments

Before construction starts, review the project to figure out what types and amounts of waste you’ll likely have. This helps plan steps to stop waste before it happens.

2. Building a Clear Waste Management Plan

Based on your review, create a detailed waste management plan to include in the project from day one. This plan should set specific targets for waste reduction, assign roles for sorting and handling, and lay out how materials will reach recycling plants or recovery centers.

3. Designing to Use Materials Smarter

Architects and designers have a big impact on waste. Using standard sizes and better layouts means fewer offcuts and less scrap. Simple planning tools like BIM (Building Information Modeling) can help order the right materials and flag waste risks before construction.

4. Choosing Materials: You Can Reuse or Recycle

Pick materials that are recycled or that can be recycled again. Whenever possible, reuse parts from old buildings or choose products with high recycled content. More suppliers now offer or accept used items, making it easier to keep waste out of landfills.

5. Working With Suppliers for Return Options

Talk to suppliers early about bringing back unused materials. Some offer take-back programs, especially for things like drywall or pallets. Ordering just what you need and trusting accurate estimators- keeps surplus waste and costs low.

Ideal Job Site Practices to Waste Less and Work Smarter

Once work starts, it’s all about following good practices to reduce waste.

Smart Ordering and Storage

Handle materials carefully to avoid damage. Store everything safely and out of the elements. Schedule deliveries so materials arrive as needed, reducing clutter. Check inventory regularly to avoid extra orders.

On-Site Waste Sorting and Recycling

Set up labeled bins to sort wood, metal, concrete, cardboard, and trash. Teach the crew to separate as they work. Most construction waste that ends up in landfill could have been recycled if sorted early.

Using Prefab and Modular Building Methods

Off-site manufacturing cuts down on mistakes and leftover scraps. Pieces made in factories are more accurate, with any unused bits reused on other jobs. Modular systems also let builders use materials more efficiently.

Reducing Errors Through Lean Building

Streamlined workflows mean less waste of time and materials. Lean construction focuses on cutting errors and rework, lowering wasted materials and delays.

Clear Team Communication

When everyone understands what’s needed, there is less confusion and waste. Digital tools and shared updates help everyone stay on track for waste reduction goals.

Training, Policy, and Teamwork

Technology and plans help only if people follow them. Training and clear processes are key.

Training Workers

Make sure everyone knows how to handle and separate materials properly. Ongoing sessions keep crews aware of both techniques and the reasons they matter. Training helps build habits that protect the environment.

Set Goals and Track Progress

Give teams clear targets — like sending 80% of waste for recycling. Regularly measure results so you can see improvements or spot problems.

Include Everyone in the Process

Get everyone involved, from designers to subcontractors to waste haulers. Shared responsibility and open communication create better, consistent results.

Next Steps for More Efficient, Less Wasteful Construction

Zero-waste construction is a work in progress. Keep moving forward by doing the following.

Keep Getting Better and Trying New Ideas

Always look for better ways to handle materials using new products or methods to reuse parts. Adjust your plans and tech as you learn from each job.

Pay Attention to Changing Rules

New waste regulations appear regularly. Staying aware of these helps businesses stay compliant and avoid costly mistakes. Taking action early puts companies ahead of the game.

Use Available Resources to Improve Waste Management

Groups like the EPA have useful guides for planning, training, and using technology. These free resources can help any team build a better waste management program.

Conclusion

Cutting construction waste and boosting efficiency isn’t just a good idea. It’s becoming necessary to stay successful.

By adopting these practical steps, companies can build more affordably, safely, and responsibly, working toward a building industry where resources are valued and reused, not wasted.